Building an Ice House for Year Round Refrigeration

In the pursuit of self-sufficiency, one traditional method that has seen a resurgence among modern homesteaders and off-grid enthusiasts is the use of an ice house. An ice house, once a staple before the advent of electric refrigeration, offers a reliable solution for long-term cold storage, especially in remote areas where electricity is either unavailable or unreliable. This age old technology allows for the preservation of perishables over extended periods which allows for a steady supply of food throughout the year.

It was common back pre 1970 that ice houses were commercial businesses and typically would see the owner use a chain saw to cut blocks of ice out of a frozen lake and then pull them back to the ice house by horse and sled. This ice would be backed in many inches of sawdust and would last in a quality insulated house until the next winter.

For those living off the grid or preparing for scenarios where modern conveniences might not be available, building an ice house is not just about embracing historical practices—it’s about ensuring food security and independence. The revival of ice houses on contemporary homesteads isn’t just a nod to the past; it’s a practical, sustainable choice that aligns with the values of reducing reliance on modern utilities and enhancing one’s ability to survive and thrive in any situation.

The ice house holds a venerable place in the annals of human history, dating back to ancient times when Persians stored ice and snow in desert climates using subterranean structures. In Europe and North America, during the 19th century, before the widespread availability of refrigeration technology, ice houses were commonplace on farms and large estates. These structures were not only practical but essential for preserving food and providing ice throughout the year.

Whether your interest lies in the ecological benefits of using natural cooling systems or in the prepping perspective of being ready for any emergency, an ice house can be a valuable addition to your homestead. This guide will walk you through the why and how of building your own ice house, covering everything from the initial planning stages to the construction details and maintenance.

Why Build an Ice House?

Practical Benefits for Homesteaders and Preppers

For homesteaders, the practical benefits of an ice house are manifold:

- Energy Independence: Ice houses require no electricity, which is ideal for off-grid living situations. They provide a way to keep food cold without ongoing energy costs, reducing your homestead’s carbon footprint.

- Food Preservation: They are perfect for storing seasonal harvests, dairy products, and meat over the winter months when other preservation methods might fail due to power outages or other disruptions.

- Emergency Preparedness: In emergency situations where power might be lost for an extended period, having an ice house can mean the difference between preserving your food supply and facing spoilage.

As communities increasingly look to reduce their dependence on modern supply chains and utility grids, ice houses offer a way to reclaim a piece of forgotten technology that is both effective and environmentally friendly. Building an ice house is not just about preparing for a worst-case scenario; it’s about choosing a lifestyle that values sustainability, preparedness, and historical wisdom.

Planning Your Ice House

Location Selection

Choosing the right location for your ice house is critical to its effectiveness and efficiency. Ideally an ice house dug into or embedded into the earth is your best bet for natural insulation. Alternatively, putting you ice house in your basement or dugout is also a viable option although keep in mind that ice is heavy and you will need to get it into the area.

Here are several factors to consider:

- Sun Exposure: Select a site with minimal sun exposure, preferably shaded or on the north side of a building or hill. This reduces the amount of heat absorbed by the structure during the day, keeping the interior as cool as possible.

- Drainage: Ensure the area has good drainage to prevent water from entering the ice house. Water ingress can cause the ice to melt faster and can lead to structural damage over time.

- Accessibility: The ice house should be conveniently located close to your kitchen or pantry for easy access, but not so close that it could cause issues with humidity or pests.

Size and Scale

Determining the right size for your ice house depends on your storage needs and the size of your homestead:

- Household Size: Consider how much food you typically need to store. A larger family or one that harvests a lot of produce might need more space than a single person or a small family.

- Usage Frequency: How often will you access the ice house? Frequent access can lead to more warm air entering and may require a larger volume of ice to maintain low temperatures.

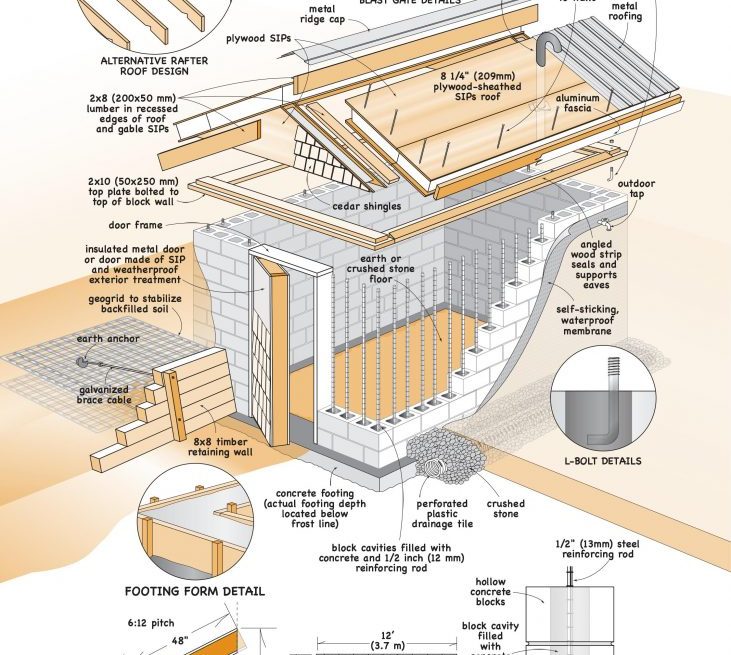

Materials Needed

The choice of materials will greatly influence the effectiveness and longevity of your ice house:

- Insulation: Traditional materials like sawdust and straw are excellent for insulation and are often readily available on a homestead. Modern alternatives like foam insulation or fiberglass can also be used, especially around the door and roof for enhanced thermal efficiency.

- Walls and Flooring: Thick wooden walls are traditional, but stone or concrete can also be used for added durability and better cold retention. The floor should be slightly sloped towards a drain to allow meltwater to exit the structure easily.

- Roofing: The roof should be sturdy and well-insulated. Materials like thick wooden beams covered with insulating layers and waterproof membranes can be effective.

Preparing for Winter: Storing Ice

Properly gathering and storing ice is crucial for maintaining your ice house through the warmer months. Here’s how you can effectively harvest and store ice during the winter to ensure your ice house remains functional year-round.

Harvesting Ice

- Selecting the Source:

- Natural Sources: If you have access to a clean pond, lake, or river that freezes over, these can be excellent sources of ice. Ensure the water is safe and free from pollutants.

- Creating Ice Blocks: If natural clean ice is unavailable, you can create large blocks of ice by filling containers with water and leaving them outside to freeze.

- Cutting and Extracting Ice:

- Tools Required: The most common tool for cutting ice blocks is a chain saw, but you can also use ice saws, chisels, and ice spuds for cutting ice from natural sources. These tools help you control the size and shape of the ice blocks.

- Technique: Mark a grid pattern on the ice to create uniform blocks. Cut through the ice along the marked lines, then use an ice spud or chisel to pry the blocks free.

- Transporting Ice:

- Sleds or Carts: Transport the ice blocks using sleds, skis, or wheeled carts to your ice house. Ensure the path is clear and stable to avoid breaking the ice.

Storing Ice

- Stacking Ice Blocks:

- Layering: Start by laying a base layer of straw or sawdust on the floor of the ice house. Stack the ice blocks tightly together to reduce air exposure, which minimizes melting.

- Insulation Between Layers: Between each layer of ice, add more insulating materials such as sawdust or straw. This insulation prevents the blocks from freezing together and provides additional thermal protection.

- Maintenance:

- Regular Checks: Throughout the winter and into the warmer months, check the ice house regularly for signs of melting or gaps in insulation. Add more sawdust or straw as needed to areas where the ice appears to be melting faster.

- Drainage: Ensure that the drainage system within the ice house is functioning properly to deal with any water from melted ice. Proper drainage is crucial to prevent the bottom layers of ice from sitting in water, which would speed up the melting process.

- Maximizing Ice Longevity:

- Minimize Opening: Open the ice house as infrequently as possible to prevent warm air from entering and accelerating ice melt.

- Optimal Conditions: Maintain the interior of the ice house at just above 0°C (32°F) for optimal ice preservation. Regular temperature checks can help manage the internal climate efficiently.

Longevity of Ice in Storage

The duration for which ice can be preserved in an ice house depends on several factors, including the quality of construction, insulation, and external weather conditions. However, with optimal construction and maintenance, ice stored in an ice house can last from the late winter months when it is harvested until the next winter season begins, essentially providing cold storage throughout the warmer months. Here are key factors that affect the longevity of ice and how to optimize them:

Construction Quality

- Insulation: Effective insulation is the most critical factor in extending the life of ice. Using materials such as sawdust, straw, or modern insulating foams can greatly reduce the rate of melting. Walls and roofs should be well-insulated to minimize heat ingress.

- Seal: Ensure that the structure is well-sealed. Gaps in the door or walls can let in warm air, which accelerates melting. Use weather stripping around the door and seal any visible cracks.

Storage Technique

- Packing Ice Tightly: Ice should be cut into large, uniform blocks and packed tightly together to reduce surface area exposure, which decreases melting.

- Layering with Insulation: Between layers of ice, add a generous amount of insulating material like sawdust or straw. This not only prevents the blocks from freezing together but also adds an additional barrier against heat.

External Conditions

- Shade and Ventilation: Positioning the ice house in a shaded area and ensuring adequate ventilation can help maintain low internal temperatures. Ventilation helps to expel warmer air that rises within the structure without letting in too much warm external air.

- Climate: Naturally, the climate plays a significant role. In cooler, northern climates, ice can last longer than in warmer, southern areas. Adjusting insulation thickness and the frequency of ice house access can help compensate for warmer climates.

Maintenance and Monitoring

- Regular Checks: Regular inspection of the ice house for signs of structural compromise or excessive melting is important. Repair any damage promptly.

- Temperature and Humidity Control: Monitor the internal temperature and humidity levels using simple tools like thermometers and hygrometers. Keeping the internal environment stable is key to prolonging the ice’s lifespan.

Related Links

How to Build an Ice House

https://www.motherearthnews.com/diy/build-an-ice-house-zmaz72soztak/